Optimize your operations with FAI Engineering!

Looking to develop your business on WhatsApp? I'm here to help!

FAI Engineering

Design and Installation of Sustainable Industrial Processes

For over 30 years, FAI Engineering has been your preferred partner for the engineering and installation of food processing projects. Specialized in the design of innovative industrial processes, we put our expertise to work for your performance, while respecting environmental issues.

FAI Engineering

Design and Installation of Sustainable Industrial Processes

For over 30 years, FAI Engineering has been your preferred partner for the engineering and installation of food processing projects. Specialized in the design of innovative industrial processes, we put our expertise to work for your performance, while respecting environmental issues.

Vegetables

Fruits

Seafood

Fishs

Meats

Innovation at the service of your performance

Our mission is to design and deliver innovative engineering solutions that optimize our customers' industrial processes while minimizing environmental impact. We are committed to accompanying our partners towards cost reduction and sustainable, responsible growth.

6

ZONA DEL SALMÓN

5

PRECOOLING ZONE

4

KITCHEN AREA

3

HOMOGENIZATION OF ZONES

2

DEFROSTING ZONES

1

DESTRUCTURING AREA

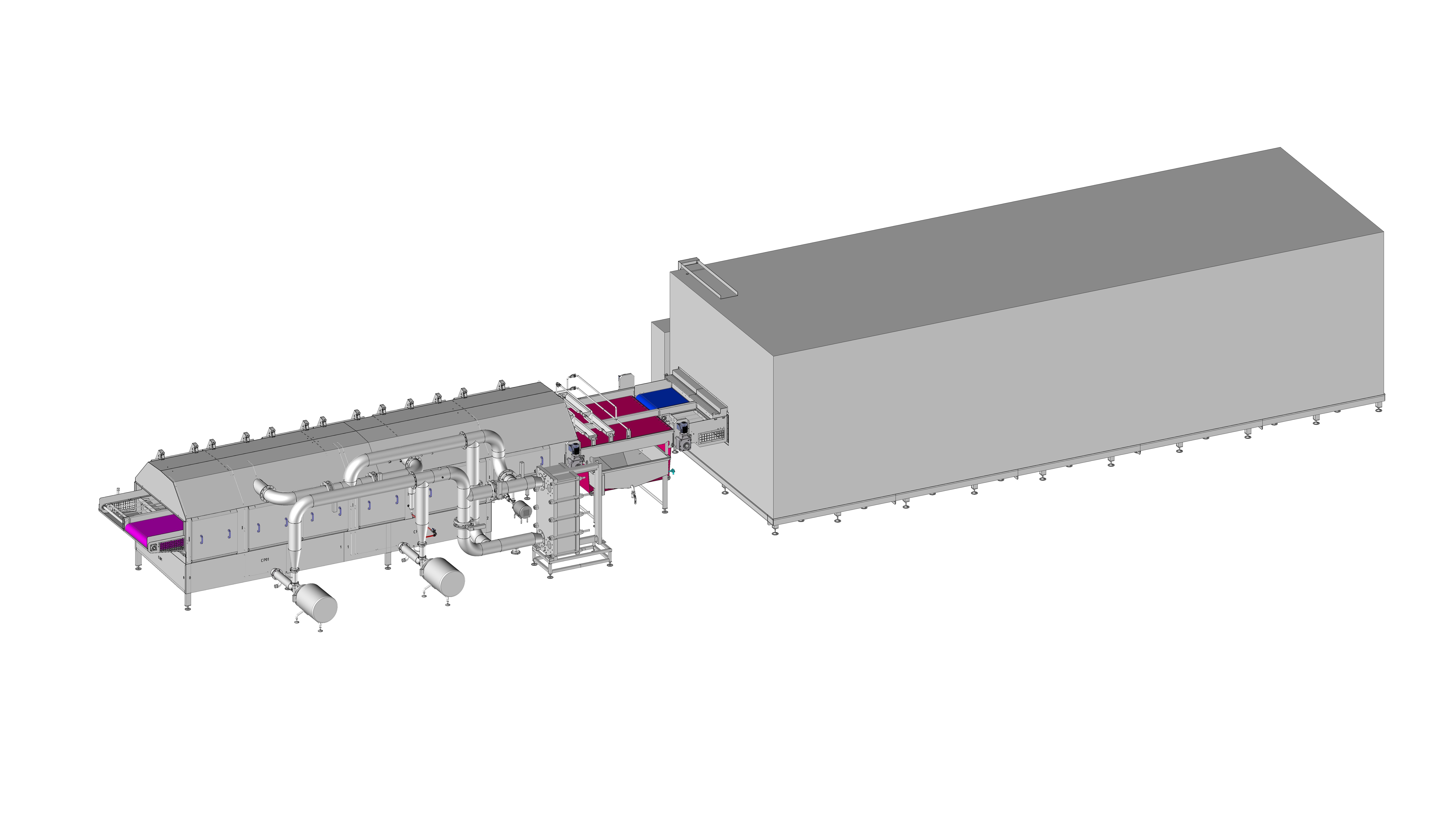

Cooking line

3

BOTTLE WITH REFRIGERANT

2

SCREW COMPRESSOR WITH VARIATOR SPEED

1

2

SCREW COMPRESSOR WITH VARIATOR SPEED

4

BOUTEILLE BP AT DIFFERENT T°C

4

BOUTEILLE BP AT DIFFERENT T°C

SKID cooling system

6

ZONA DEL SALMÓN

5

PRECOOLING ZONE

4

KITCHEN AREA

3

HOMOGENIZATION OF ZONES

2

DEFROSTING ZONES

1

DESTRUCTURING AREA

Cooking line

3

BOTTLE WITH REFRIGERANT

2

SCREW COMPRESSOR WITH VARIATOR SPEED

1

2

SCREW COMPRESSOR WITH VARIATOR SPEED

4

BOUTEILLE BP AT DIFFERENT T°C

4

BOUTEILLE BP AT DIFFERENT T°C

SKID cooling system

6

ZONA DEL SALMÓN

5

PRECOOLING ZONE

4

KITCHEN AREA

3

HOMOGENIZATION OF ZONES

2

DEFROSTING ZONES

1

DESTRUCTURING AREA

Cooking line

3

BOTTLE WITH REFRIGERANT

2

SCREW COMPRESSOR WITH VARIATOR SPEED

1

2

SCREW COMPRESSOR WITH VARIATOR SPEED

4

BOUTEILLE BP AT DIFFERENT T°C

4

BOUTEILLE BP AT DIFFERENT T°C

SKID cooling system

6

ZONA DEL SALMÓN

5

PRECOOLING ZONE

4

KITCHEN AREA

3

HOMOGENIZATION OF ZONES

2

DEFROSTING ZONES

1

DESTRUCTURING AREA

Cooking line

3

BOTTLE WITH REFRIGERANT

2

SCREW COMPRESSOR WITH VARIATOR SPEED

1

2

SCREW COMPRESSOR WITH VARIATOR SPEED

4

BOUTEILLE BP AT DIFFERENT T°C

4

BOUTEILLE BP AT DIFFERENT T°C

SKID cooling system

ZONA DEL SALMÓN

PRECOOLING ZONE

KITCHEN AREA

HOMOGENIZATION OF ZONES

DEFROSTING ZONES

DESTRUCTURING AREA

Cooking line

2

1

3

4

5

6

1

2

3

4

5

6

BOUTEILLE BP AT DIFFERENT T°C

BOTTLE WITH REFRIGERANT

SCREW COMPRESSOR WITH VARIATOR SPEED

ELECTRICAL CABINET

SKID cooling system

2

1

3

4

1

2

3

4

2

4

ZONA DEL SALMÓN

PRECOOLING ZONE

KITCHEN AREA

HOMOGENIZATION OF ZONES

DEFROSTING ZONES

DESTRUCTURING AREA

Cooking line

2

1

3

4

5

6

1

2

3

4

5

6

BOUTEILLE BP AT DIFFERENT T°C

BOTTLE WITH REFRIGERANT

SCREW COMPRESSOR WITH VARIATOR SPEED

ELECTRICAL CABINET

SKID cooling system

2

1

3

4

1

2

3

4

2

4

ZONA DEL SALMÓN

PRECOOLING ZONE

KITCHEN AREA

HOMOGENIZATION OF ZONES

DEFROSTING ZONES

DESTRUCTURING AREA

Cooking line

2

1

3

4

5

6

1

2

3

4

5

6

BOUTEILLE BP AT DIFFERENT T°C

BOTTLE WITH REFRIGERANT

SCREW COMPRESSOR WITH VARIATOR SPEED

ELECTRICAL CABINET

SKID cooling system

2

1

3

4

1

2

3

4

2

4

ZONA DEL SALMÓN

PRECOOLING ZONE

KITCHEN AREA

HOMOGENIZATION OF ZONES

DEFROSTING ZONES

DESTRUCTURING AREA

Cooking line

2

1

3

4

5

6

1

2

3

4

5

6

BOUTEILLE BP AT DIFFERENT T°C

BOTTLE WITH REFRIGERANT

SCREW COMPRESSOR WITH VARIATOR SPEED

ELECTRICAL CABINET

SKID cooling system

2

1

3

4

1

2

3

4

2

4

6

ZONA DE SALMUERA

5

PRECOOLING ZONE

4

KITCHEN AREA

3

HOMOGENIZATION OF ZONES

2

1

DESTRUCTURING AREA

Cooking line

3

BOTTLE WITH REFRIGERANT

2

SCREW COMPRESSOR WITH VARIATOR SPEED

1

2

SCREW COMPRESSOR WITH VARIATOR SPEED

4

BOUTEILLE BP AT DIFFERENT T°C

4

BOUTEILLE BP AT DIFFERENT T°C

SKID cooling system

6

ZONA DE SALMUERA

5

PRECOOLING ZONE

4

KITCHEN AREA

3

HOMOGENIZATION OF ZONES

2

1

DESTRUCTURING AREA

Cooking line

3

BOTTLE WITH REFRIGERANT

2

SCREW COMPRESSOR WITH VARIATOR SPEED

1

2

SCREW COMPRESSOR WITH VARIATOR SPEED

4

BOUTEILLE BP AT DIFFERENT T°C

4

BOUTEILLE BP AT DIFFERENT T°C

SKID cooling system

6

ZONA DE SALMUERA

5

PRECOOLING ZONE

4

KITCHEN AREA

3

HOMOGENIZATION OF ZONES

2

1

DESTRUCTURING AREA

Cooking line

3

BOTTLE WITH REFRIGERANT

2

SCREW COMPRESSOR WITH VARIATOR SPEED

1

2

SCREW COMPRESSOR WITH VARIATOR SPEED

4

BOUTEILLE BP AT DIFFERENT T°C

4

BOUTEILLE BP AT DIFFERENT T°C

SKID cooling system

6

ZONA DE SALMUERA

5

PRECOOLING ZONE

4

KITCHEN AREA

3

HOMOGENIZATION OF ZONES

2

1

DESTRUCTURING AREA

Cooking line

3

BOTTLE WITH REFRIGERANT

2

SCREW COMPRESSOR WITH VARIATOR SPEED

1

2

SCREW COMPRESSOR WITH VARIATOR SPEED

4

BOUTEILLE BP AT DIFFERENT T°C

4

BOUTEILLE BP AT DIFFERENT T°C

SKID cooling system

Take a look at our latest transformation lines

A shrimp farming company in Madagascar wanted to modernize its facilities to increase production capacity while improving product quality.

INNOVATIVE TECHNICAL SOLUTIONS

INNOVATIVE TECHNICAL SOLUTIONS

FAI Engineering has its own design and R&D department. We offer innovative technical solutions that are the perfect answer to your food processing needs.

FAI Engineering has its own design and R&D department. We offer innovative technical solutions that are the perfect answer to your food processing needs.

FAI Engineering has its own design and R&D department. We offer innovative technical solutions that are the perfect answer to your food processing needs.

innovation goes hand in hand with sustainability

At FAI Engineering, we believe that innovation must go hand in hand with sustainability.

Certifications

CE standards :

Our equipment complies with

and hygiene standards.

Invention patent :

We regularly register patents

for our innovations.

Initiatives

Energy efficiency :

Our technologies reduce

our customers' energy consumption.

Formation :

We train our customers' teams

to sustainable and efficient practices.

FAQ

1. What types of products can you handle with your equipment?

Our technologies are suitable for a wide range of food products, including seafood, meats, vegetables and more.

2. Do you offer customized equipment?

3. How do your technologies contribute to sustainable development?

4. Do you offer after-sales service?

5. How to get started with FAI Engineering

1. What types of products can you handle with your equipment?

Our technologies are suitable for a wide range of food products, including seafood, meats, vegetables and more.

2. Do you offer customized equipment?

3. How do your technologies contribute to sustainable development?

4. Do you offer after-sales service?

5. How to get started with FAI Engineering

1. What types of products can you handle with your equipment?

Our technologies are suitable for a wide range of food products, including seafood, meats, vegetables and more.

2. Do you offer customized equipment?

3. How do your technologies contribute to sustainable development?

4. Do you offer after-sales service?

5. How to get started with FAI Engineering

Contact with us

Do you have any request or question? Do not hesitate to

send us an e-mail or call us at +33 2 51 70 65 65

Contact with us

Do you have any request or question? Do not hesitate to

send us an e-mail or call us at +33 2 51 70 65 65

Contact with us

Do you have any request or question? Do not hesitate to send us an e-mail or call us at +33 2 51 70 65 65

Address

D2A Nantes-Atlantique

8 rue René Fonck

44860 Saint Aignan

de Grand Lieu

France

France Agro Industries

SAS au capital de 152 500 €

SIRET 339 746 869 00025

RCS NANTES

Code NAF 7112B

Address

D2A Nantes-Atlantique

8 rue René Fonck

44860 Saint Aignan

de Grand Lieu

France

France Agro Industries

SAS au capital de 152 500 €

SIRET 339 746 869 00025

RCS NANTES

Code NAF 7112B

Address

D2A Nantes-Atlantique

8 rue René Fonck

44860 Saint Aignan

de Grand Lieu

France

France Agro Industries

SAS au capital de 152 500 €

SIRET 339 746 869 00025

RCS NANTES

Code NAF 7112B