BENEFITS

✓ Modular construction with a compact footprint for easy installation.

✓ A high exchange coefficient enables rapid lowering of the product to the core.

✓ IQF product guaranteed without weight loss.

✓ Reduced product handling with the possibility of using different packaging.

✓ Easier operation thanks to reduced brine mass and automatic adjustment of brine concentration.

✓ Possibility of glazing.

✓ Designed for fast maintenance and cleaning.

✓ Special safety approval to CE standards.

✓ Reduced operating costs.

| Line TDC FAI | TDC 100 | TDC 200 | TDC 500 | TDC 1000 | TDC 1500 | TDC 2000 | TDC 2500 | TDC 3000 | TDC 3500 | TDC 4000 | TDC 5000 | TDC 6000 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity kg/h – Capacité kg/h – Capacidad kg/h | ||||||||||||

| Process time | from 8 to 30 minutes | |||||||||||

| L (m) | from 6 to 35 m | |||||||||||

| W (m) | from 2,8 to 4,8 m | |||||||||||

| H (m) | from 2,5 to 3,8 m | |||||||||||

| Manufacture | Stainless steel 316 L – Inox 316 L – Acero inoxidable 316 L | |||||||||||

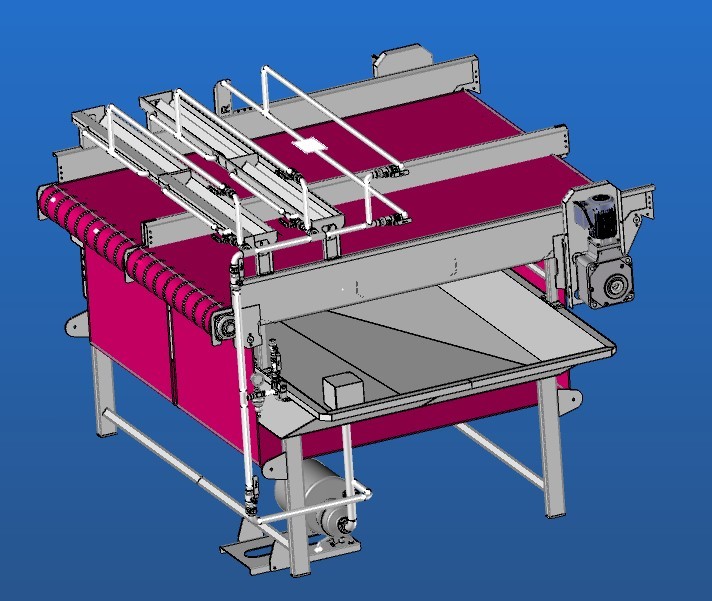

FAI TDC LINES

The patented freezing tunnel is designed to freeze the product very quickly, with the brine trickling technique providing a high exchange coefficient.

The process comprises a brine freezing zone - draining zone, followed or not by glazing and a sub-cooling zone.

Brine ZONE

Our brine tanks are made of 316L stainless steel with a double skin to prevent heat loss and extend brine shelf life. We have a manual salinizer built into the machine, and an automatic external salinizer to facilitate brine preparation. The external salinizer is equipped with a pump and agitator. Brine concentration is controlled automatically.

GLAZING ZONES

The unit is designed to be self-contained and can be integrated into existing processes with ease.

Glazing is the process by which a glazed surface is formed.

protective layer of ice on the product. Glazing also enables frozen products to be rinsed in brine.

3 ramps are available:

- Nozzle spraying

- Water runoff

- Perforated runoff

The operator operates the ramps according to the required rate of required glazing rate.

ZONE UNDER COOLING

This zone is equipped with an isolation cell to maintain a low-temperature atmosphere, thanks to an air recirculation system comprising fans and evaporators. The air in this zone is at a constant negative temperature (-28°C to -40°C).

Optimize your operations with FAI Engineering!

Looking to develop your business on WhatsApp? I'm here to help!